Covid-19: We keep working under the most strict health and safety protocols

How can we help you with your Life Line project?

A successful Life Line Project requires two variables: knowledge of work at heights and engineering design that defines how the life lines will be installed to guarantee that will accomplish their purpose. We are specialists in work at height and have a highly experienced engineering department that has plenty of work in life line solutions.

Life Lines

Work at height is one of the main causes of accidents and fatalities at worksites. For example, in the UK falls from height represent a third of all the deadly work accidents and almost 60% of all labour accidents. An additional factor is that in this type of incidents the magnitude of the injury usually is greater, particularly in the head.

The best way this situation is through an integral Fall Protection program that not only will protect workers from potential falls but also will improve the performance and productivity of workers. The core of such a program is to install specialized systems for fall detention and restriction, known as Life Lines. Also is necessary to train the staff, so they can be aware of the risks and procedures related to work at heights.

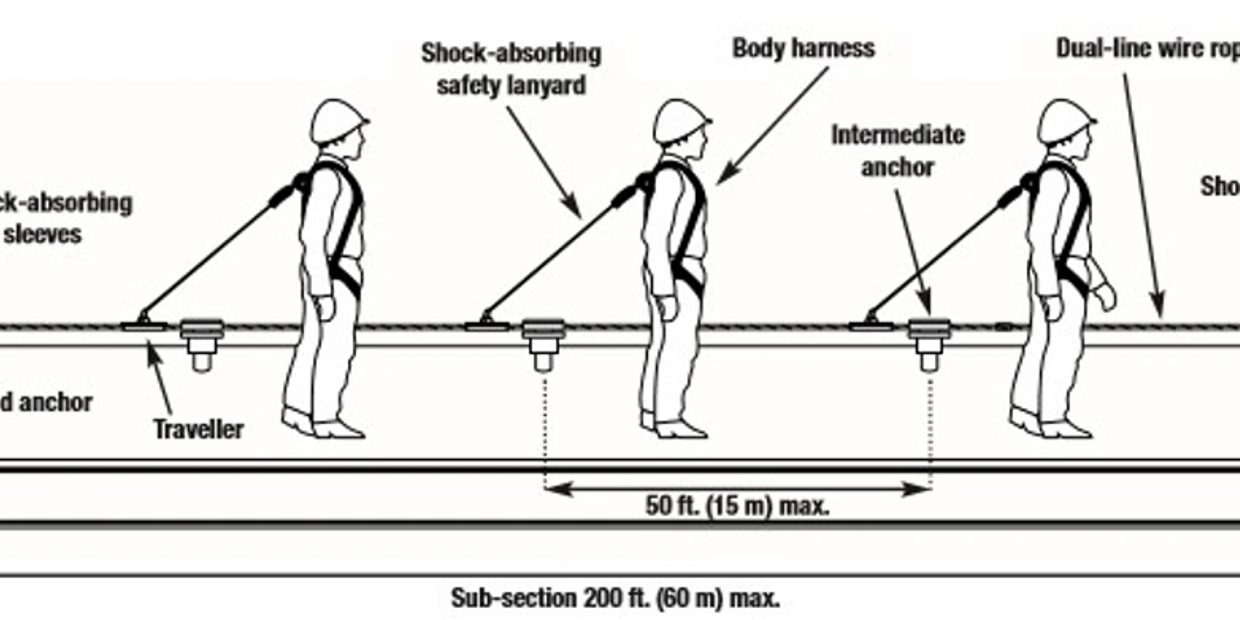

A Life Line system is comprised of steel cables that are anchored to fixed points. The user is connected with a safety lanyard and a harness to a shuttle (traveller) that goes across the steel cables. With this life line system a person can move easily and with safety, being certain that, in case of an accident, the system will stop or restrict the fall.

Installation and quality material

Life lines are much more than just tightened cables and, for that reason, is dangerous to assume that the more tight is the cable the more safe the system will be. Or that even just adding extra stables at the anchor points will suffice to stop a fall. The efforts in the end anchors are exponentially higher to the weight of a person. For this reason is very important a thoughtful engineering project, previous to the installation, that considers all use and structural variables.

Travsafe®

We sell Travsafe® life lines, manufactured by Tractel®. They comply with all ANSI, OSHA and CSA regulations and are make with galvanized steel. Their maximum load capacity is 5,000 lbs and can have up to five persons at the same time. Its design allows for smooth travel, withou interruptions.

Travsafe Permanent Life Line System

Extreme support

%2017.32.2.png/:/cr=t:0%25,l:7.63%25,w:84.75%25,h:100%25/rs=w:814,h:407,cg:true)

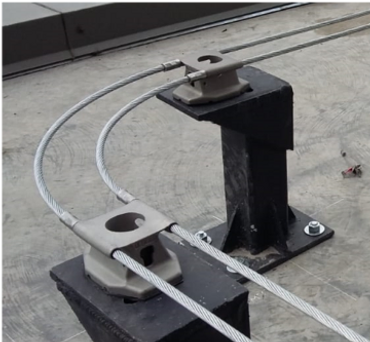

It consists of a galvanized steel support that is place at the beginning and at the end of each section.

Intermediate Support

It is a galvanized steel support that is placed as an intermediate support in the sections of each life line. It is installed at a maximun distance of 15 meters.Es un soporte de acero galvanizado que se coloca como apoyo intermedio en los recorridos de cada tramo de línea. Se coloca a cada 15 m como máximo.

Shuttle (Traveller)

%2017.37.3.png/:/cr=t:0%25,l:2.83%25,w:94.34%25,h:100%25/rs=w:814,h:407,cg:true)

It is a small steel shuttle that has a travelling anchor point over the cable of the life line.

Galvanized steel cable

It is a 9 mm diameter galvanized steel cable.

%2017.45.2.png/:/rs=w:370,cg:true,m)

%2017.45.4.png/:/rs=w:370,cg:true,m)

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.